4 Types of Maintenance Strategy

4 Types of Maintenance Strategy

The optimal performance and longevity of assets are guaranteed by maintenance, which is an essential component of any operation. Diverse maintenance strategies are implemented to accomplish diverse objectives. The following are four prevalent types:

1. Preventive Maintenance

The scheduled inspection and servicing of apparatus are part of preventive maintenance, which is designed to prevent failures and breakdowns. Preventive maintenance can significantly reduce downtime and enhance the overall reliability of equipment by routinely inspecting for wear and tear, cleaning components, and replacing parts before they fail.

Preventive maintenance (PM) is a strategic asset management approach that entails the routine inspection, servicing, and maintenance of equipment to prevent costly repairs and unforeseen failures. In contrast to reactive maintenance, which entails the resolution of issues after they have occurred, PM is designed to identify and resolve potential issues prior to their escalation to a critical level. This proactive strategy has the potential to enhance asset reliability, minimize disruption, and optimize operational efficiency.

The Significance of Preventive Maintenance

Businesses of all sizes can derive numerous advantages from preventive maintenance. The following are a few of the primary benefits:

Increased Equipment Uptime:

PM ensures that equipment remains operational for extended periods by identifying and resolving potential issues prior to their development into defects. This is especially crucial in sectors where operational and financial repercussions may be substantial.

Decreased Maintenance Costs:

PM can assist in the prevention of costly emergency repairs, thereby reducing overall maintenance costs. Businesses can prevent the necessity for costly repairs and replacements by proactively addressing issues.

Enhanced Safety:

Safety hazards can be identified and resolved prior to the occurrence of accidents or injuries through routine inspections and maintenance. This is especially crucial in sectors where the public or employees may be at risk due to equipment malfunctions.

Increased Asset Lifespan:

Businesses can increase the value of their assets and extend the duration of their equipment by conducting routine maintenance. This is particularly crucial for apparatus that is costly or requires specialized capabilities.

Enhanced Planning and Budgeting:

PM enables businesses to more effectively plan and budget for maintenance expenses. Businesses can prevent unforeseen expenses and disruptions by preplanning maintenance duties.

Establishing a Preventive Maintenance Program

Businesses must adhere to a structured methodology in order to execute an effective PM program. These are the primary procedures:

1. Asset Inventory: Develop an exhaustive inventory of all assets that necessitate maintenance. This should encompass details such as the manufacturer, model number, type, and age of the apparatus.

2. Risk Assessment: Determine the critical assets that are most susceptible to significant disruptions or failures in the event of their malfunction. Determine the risk associated with each asset and prioritize maintenance efforts accordingly.

3. Maintenance Schedule: Establish a schedule for routine inspections, maintenance duties, and replacements. Historical failure data, manufacturer recommendations, and equipment utilization are all factors to be taken into account.

4. Resource Allocation: Guarantee that the PM program is adequately supported by a sufficient supply of personnel, equipment, and spare parts.

5. Documentation and Recordkeeping: Maintain comprehensive records of all maintenance activities, such as the results of inspections, the repairs that were completed, and the replacement parts that were employed. This data can be employed to optimize the PM program, identify trends, and monitor equipment performance.

6. Performance Evaluation: Conduct routine evaluations of the PM program’s effectiveness to pinpoint areas that require improvement. Take into account factors such as safety performance, maintenance costs, and equipment availability.

Read more:

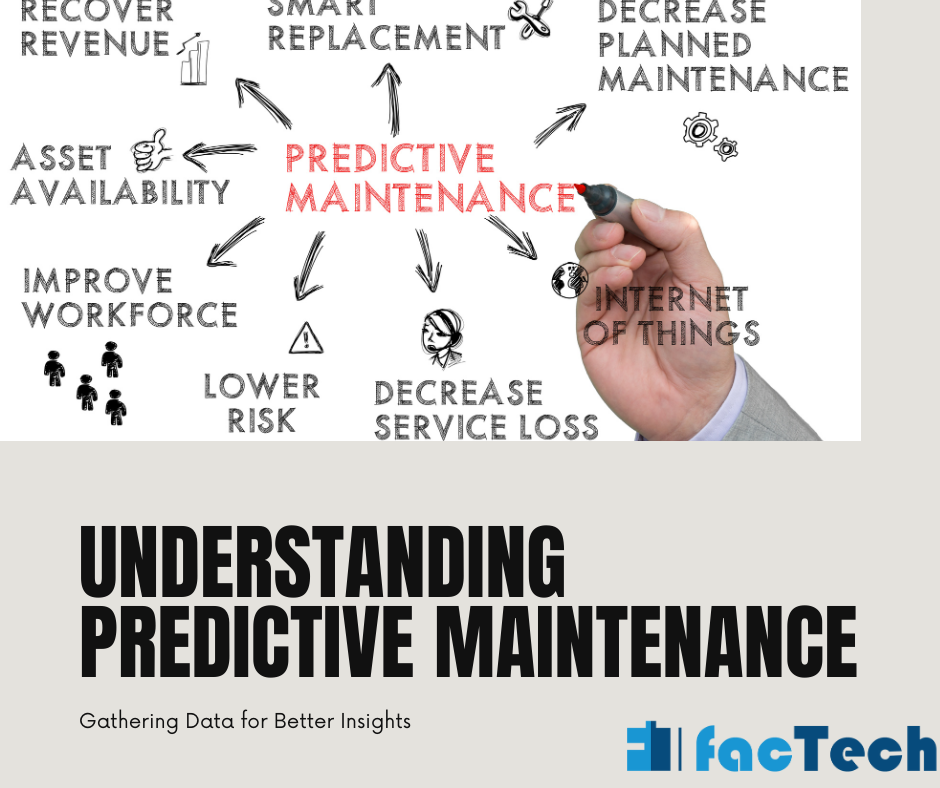

2. Predictive Maintenance

Predictive maintenance employs sophisticated technologies, including data analytics and sensors, to continuously assess the condition of equipment. It can detect potential defects prior to their occurrence by examining data patterns, thereby enabling the timely completion of repairs and maintenance.

In a time when productivity, revenue, and customer satisfaction can be substantially impacted by downtime, proactive maintenance strategies have become increasingly important. Powerful tools have emerged to optimize asset performance and reduce unexpected failures through predictive maintenance, a data-driven approach. Predictive maintenance allows organizations to extend asset lifespans, schedule maintenance duties efficiently, and anticipate equipment failures by utilizing advanced technologies and analytics.

Comprehending Predictive Maintenance

Predictive maintenance is the process of gathering and analyzing data from a variety of sources, including historical maintenance records, operational data, and sensors, in order to anticipate equipment failures before they occur. Organizations can reduce downtime and prevent costly emergency repairs by proactively scheduling maintenance and identifying potential issues early on.

Primary Elements of Predictive Maintenance

1. Data Acquisition:

Sensors: The installation of sensors on equipment to collect real-time data on vibration, temperature, pressure, and other pertinent parameters. *

Historical Data: The collection of historical maintenance records, equipment specifications, and operating conditions.

Machine Learning: The utilization of machine learning algorithms to identify patterns and anomalies within the collected data.

2. Data Analysis:

Statistical Analysis: Utilizing statistical methods to interpret data trends and identify potential correlations.

Machine Learning Models: Creating predictive models that utilize machine learning algorithms to predict the health and failure probabilities of equipment.

Visualization: Visualizing data through dashboards and charts to aid in comprehension and decision-making.

3. Condition Monitoring:

Real-time Monitoring: Consistently conducting real-time monitoring of equipment health using sensor data.

Alert Systems: Implementing alert systems to notify maintenance teams of potential issues.

Trend Analysis: The process of analyzing trends in apparatus performance to detect indicators of degradation.

4. Predictive Modeling:

Failure Prediction: Developing models to predict the likelihood of equipment failures based on historical data and current conditions.

Remaining Useful Life: Estimating the remaining useful life of assets to optimize maintenance schedules.

Risk Assessment: Prioritizing maintenance duties based on the potential risks associated with equipment failures.

5. Maintenance Optimization:

Scheduled Maintenance: The planning and scheduling of maintenance tasks using predictive models.

Resource Allocation: Optimizing the allocation of maintenance resources to maximize efficiency.

Advantages of Predictive Maintenance

1. Enhanced Equipment Reliability: Predictive maintenance significantly enhances equipment reliability and minimizes unplanned outage by identifying and resolving potential issues prior to their escalation.

2. Decreased Maintenance Costs: Organizations can achieve significant cost savings by optimizing maintenance schedules and minimizing emergency repairs.

3. Enhanced Asset Utilization: Predictive maintenance allows organizations to optimize their utilization by extending the longevity of assets and reducing downtime.

3. Corrective Maintenance

Corrective maintenance, which is frequently referred to as breakdown maintenance, is a reactive approach that addresses equipment malfunctions and failures after they have occurred. It entails the restoration or replacement of components or systems to reestablish their original functionality. Although it is an essential element of any maintenance program, the primary reliance on corrective maintenance can result in substantial disruptions, increased costs, and decreased productivity.

The Function of Corrective Maintenance

Restoring Functionality: Corrective maintenance is indispensable for the restoration of equipment’s functionality following a malfunction. It guarantees the continued operation of critical systems and processes.

Root Cause Identification: Corrective maintenance can assist in the identification of underlying issues that may contribute to future problems by examining the causes of equipment failures.

Enhancing Dependability: Proactively addressing failures can enhance the overall reliability and performance of assets over time.

Types of Corrective Maintenance

1. Emergency Maintenance: This entails the immediate repair of critical equipment that has failed or is on the brink of failure, resulting in a substantial disruption to operations.

2. Planned Corrective Maintenance: This is scheduled maintenance that is conducted to resolve known defects or issues that have been identified through inspections, testing, or condition monitoring.

3. Unanticipated Corrective Maintenance: This is the result of equipment malfunctioning unexpectedly, necessitating urgent repairs to reestablish functionality.

Combining Preventive and Corrective Maintenance

Although corrective maintenance is essential for resolving equipment malfunctions, a well-rounded maintenance program should also incorporate preventive maintenance to reduce the necessity for reactive repairs. Organizations can enhance overall operational efficiency, reduce costs, and improve equipment reliability by integrating preventive and corrective maintenance strategies.

4. Condition-based Maintenance

A strategic approach that has garnered significant traction in recent years is condition-based maintenance (CBM). CBM endeavors to enhance asset reliability and reduce outages by monitoring the real-time condition of assets and scheduling maintenance only when required. This article will delve into the complexities of CBM, examining its advantages, obstacles, and optimal methods for implementation.

Comprehending Condition-Based Maintenance

CBM is a proactive maintenance strategy that employs technology to monitor the health and performance of assets. In contrast to conventional preventive or time-based maintenance, CBM emphasizes data-driven decision-making, which enables more precise and effective maintenance interventions. CBM allows organizations to prevent costly downtime and disruptions by identifying potential failures before they occur by accumulating and analyzing data from sensors and other monitoring devices.

Critical Elements of Condition-Based Maintenance

Data Collection: Sensors and monitoring devices compile data on a variety of asset parameters, including temperature, pressure, vibration, and oil analysis.

Data Analysis: Advanced analytics techniques, such as artificial intelligence and machine learning, are employed to analyze and interpret the collected data.

Condition Assessment: The asset’s condition is evaluated to ascertain its remaining useful life and the probability of failure, based on the analyzed data.

Maintenance Scheduling: Maintenance tasks are proactively scheduled to ensure that they are performed only when necessary to prevent failures or reduce their impact.

Advantages of Condition-Based Maintenance

Improved Asset Reliability: CBM increases asset reliability and availability by identifying and addressing potential failures prior to their occurrence.

Decreased outage: Proactive maintenance reduces operational disruptions and costs by minimizing unplanned outage.

Optimized Maintenance Costs: CBM assists in the more efficient allocation of maintenance resources, thereby reducing superfluous maintenance activities and associated costs.

Enhanced Safety: CBM can assist in the prevention of accidents and injuries by identifying potential safety hazards at an early stage.

Improved Decision-Making: CBM offers organizations the ability to make data-driven decisions regarding risk management, investments, and maintenance by providing valuable insights into asset performance.

The most effective maintenance strategy is contingent upon a variety of factors, such as the criticality of the equipment to operations, the intended level of reliability, and the type of equipment. Organizations can identify the maintenance strategy that is most appropriate for their objectives and requirements by meticulously evaluating these factors.

FAQs

Q: What are the drawbacks of reactive maintenance?

A: Safety hazards, unplanned downtime, higher expenses from emergency repairs, and possible harm to other equipment.

Q: What drawbacks do preventive maintenance procedures have?

A: Possibility of excessive maintenance, higher expenses from needless repairs, and challenge in figuring out the best maintenance intervals.

Q: What is maintenance that is focused on reliability?

A: A risk-based strategy, root cause maintenance (RCM) focuses on maintaining equipment only as much as is required to prevent breakdowns that could have serious repercussions.