Machine Learning in Prescriptive Maintenance

What is Prescriptive Maintenance?

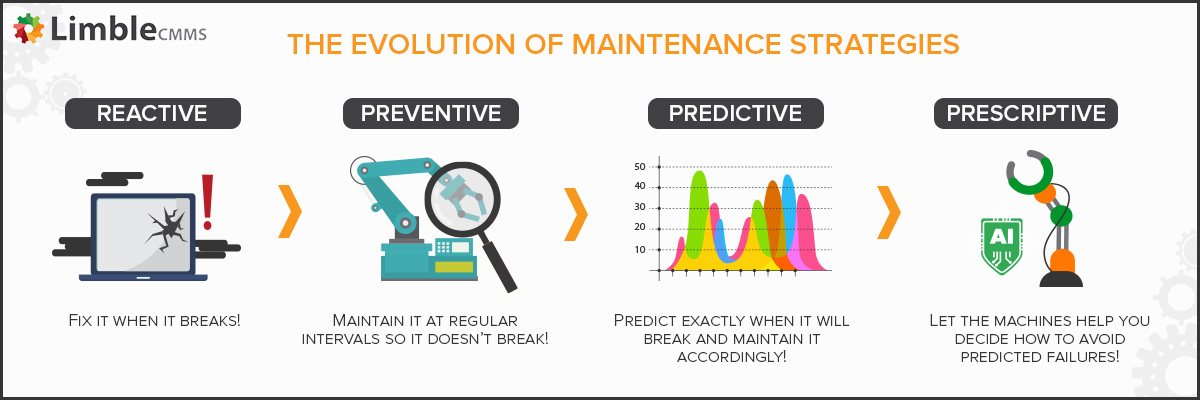

Maintenance Strategies

Predictive maintenance is a method that uses software and methods for data analysis to locate irregularities in the system and potential device and process faults so that you can repair them before they fail. Ideally, predictive maintenance allows the maintenance frequency to be as low as possible to prevent unplanned reactive maintenance, without incurring costs associated with doing too much preventive maintenance. In order to foresee concerns before they arise, predictive maintenance combines historical and real-time data from different areas of the service. When predictive maintenance is working effectively as a maintenance strategy, maintenance is only performed on machines when it is required. That is, right before it is possible that failure will occur.

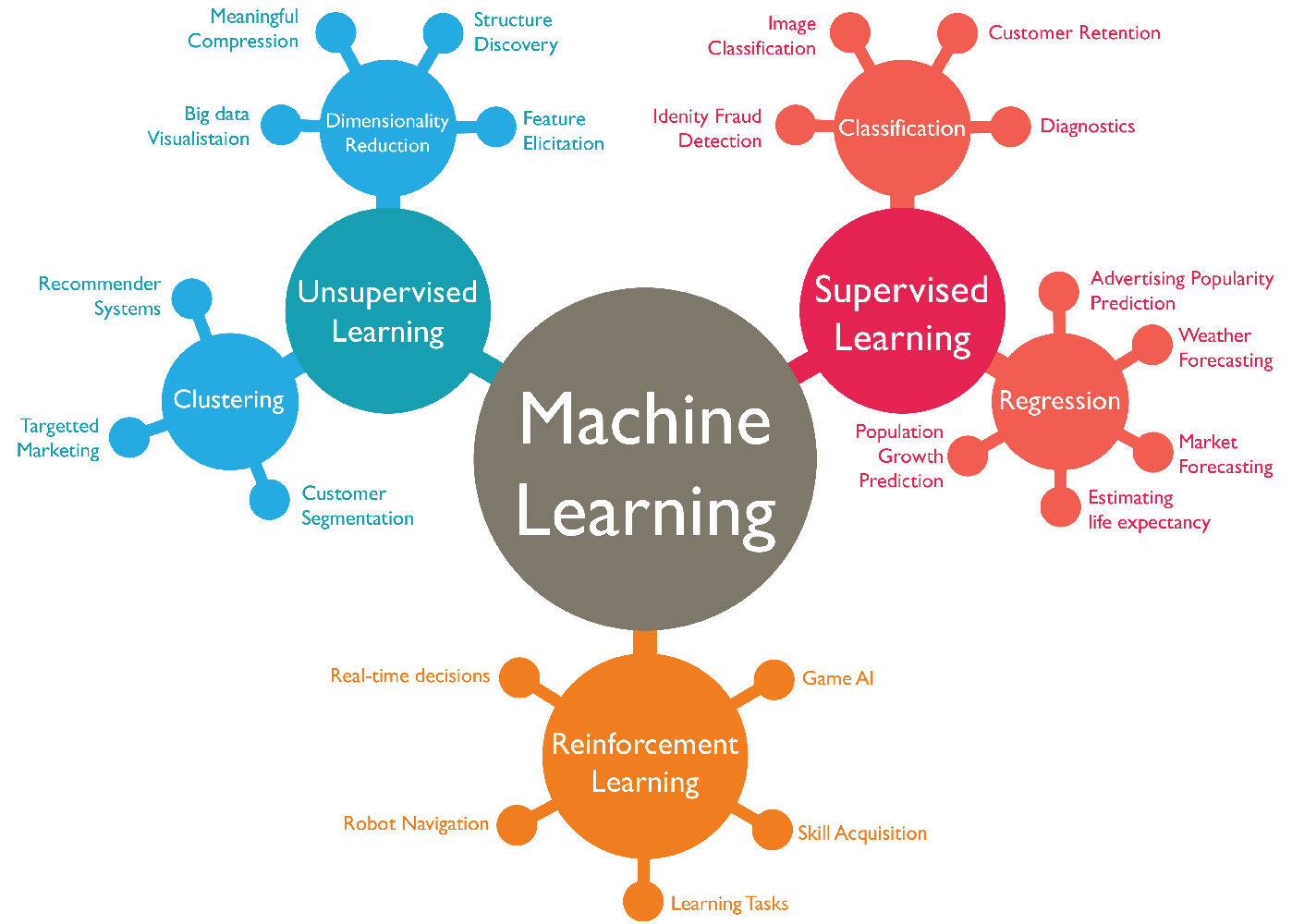

Machine learning in prescriptive maintenance

Prescriptive upkeep

Prescriptive maintenance is the technique of asset maintenance that uses machine learning to change operating conditions for desired outcomes, as well as to schedule and prepare asset maintenance intelligently. Prescriptive maintenance not only checks for failure signatures, but also includes details about how to delay or fully avoid failure of equipment. For examples of a wide range of operating conditions, these algorithms can comb historical data, and even extract patterns and extrapolate data to provide hypothetical operating environments. The prescriptive maintenance model will predict the cascade of results and consequences from minor changes to an industrial operation, enabling costly and dangerous testing to be done in a computer simulation.

A machine learning model needs to be trained on historical sensor and service data in order for prescriptive maintenance to be effective. The more high-quality data available, the more reliable the model of artificial intelligence would be, detecting more indicators of maintenance needs and signatures of weakness, while creating less false positives. Prior to being fed to the machine learning algorithm, data will need to be washed. Sensor values, for example, can need to be changed to accommodate calibration changes or standardize how human operators encode various errors.

The AI/ML system is the brain of a Prescriptive maintenance platform. ML models for production machines are designed to detect anomalous behavior during production. Training data helps to develop specific models for individual recipe steps or specific equipment types. Timely detections and prescriptions are accomplished by determining, on some continuous basis, whether a data point falls outside these bounds it is flagged as an anomaly and reported. Capability to train a new model and deploy on demand is the key. In doing so, the model is able to learn on and adapt over time.

The Factech team has been helping real estate clients in Simplifying the Facility Operations.

Contact us for a free demo of how our expertise can help you achieve your business goals.

Leave a Comment