Work Permit System Best Practices

A regulated process for guaranteeing the safe completion of work in a designated area or on certain equipment is a work permit system. It is used extensively in sectors including manufacturing, oil and gas, and construction if the action involved runs the risk of damaging equipment or causing harm. A work permit system authorizes named individuals to perform a designated job in a designated area within a designated period. It confirms that before, during, and after the job was completed, all required inspections and measures were taken. Usually linked with high-risk or hazardous activities, including working at heights, in confined spaces, with explosives, hot works, electrical work, excavation duties, and so on, are work permits. Sometimes an overall permission to work is provided for analysis and decision-making regarding whether further licenses are needed.

Understand the Work Permit System

Permits are comprehensive records defining all dangers in a job and the required safety precautions to finish a given activity at a given site; they also authorize specified individuals to operate on a particular task at a specified place. Before any construction can—or should—begin, every permit must be checked and approved by the necessary people. Once a project is finished, its permit has to be closed to record the end of the work.

Types of Permit to Work

1. Hot Work Permit

Tasks involving heat, sparks, or open flames—such as welding, soldering, or flame cutting—are authorized using Hot Work Perfumes. These licenses guarantee the presence of suitable safety precautions, such as fire watches and equipment checks, which prevent fires and explosions.

2. Cold Work Permit

Cold work permits cover jobs that can still be dangerous but lack enough heat to burn flammable materials. Examples include handling solvents, resins, or corrosive materials and completing jobs requiring significant physical effort or machine operation.

3. Confined Space Permit

Work in confined spaces—such as tanks, vessels, silos, or trenches—where access and departure options are limited calls for confined space permits. These licenses guarantee that risks, including asphyxiation, poisonous atmospheres, and engulfment, are found and reduced. Among safety precautions are appropriate ventilation, gas monitoring, and emergency rescue strategies.

4. Permission for Electrical Work

Tasks involving contact with energized electrical conductors need for electrical work permits. Maintaining safety during electrical installations, maintenance, or repairs depends on these permits, which also define particular safety procedures to avoid electrical shocks and other risks.

5. Ground Disturbance Authority

Ground Disturbance Activities involving trenching and excavation require permits. By spotting hazards such as soil collapse, striking subsurface utilities, and chemical exposure, they serve to guarantee the safety of personnel and the surroundings. For these jobs, proper planning—including identifying access and exit points and applying protective systems—is vital.

6. Reversing Containment Permission

Tasks involving the possible release of hazardous gases or liquids depend on breaking containment permits. The oil and gas sector regularly makes use of these licenses to guarantee that safety precautions are in place to stop leaks, spills, and other hazardous events. They comprise methods for safe handling and containment techniques.

7. Chemical Work Permission

Activities requiring hazardous chemicals—such as handling, mixing, or disposal of toxic or corrosive compounds—demand chemical work permits. These licenses guarantee that employees follow safety procedures, including correct handling techniques and personal protective equipment (PPE), therefore ensuring their awareness of the hazards.

8. Approved Working at Height

Jobs carried out at heights—on ladders, scaffolds, or rooftops—are handled under Height Work Permits. These licenses guarantee the presence of suitable fall protection systems, such as guardrails and harnesses, therefore avoiding falls and associated injuries.

Including these several permits in your PTW system guarantees a complete approach to occupational safety by helping to control certain hazards related to distinct activities. Understanding and using the right permissions will help companies greatly lower their risk of accidents and incidents, therefore encouraging a safer workplace.

Also, read tenant retention strategies.

Best Practices of the Work Permit System

Standardize Methodologies

Compliance and efficiency demand consistency. Across all teams and sites, apply a common framework for permits, procedures, and checklists. This guarantees everyone is aligned and reduces mistakes.

Give Training and Awareness First Priority

Every participant in the PTW process should completely know their duties and obligations. Organize frequent training courses to underline the need for correct documentation, quick approvals, and effective communication.

Require Risk Assessments

No permit should be given without careful consideration of risk. List possible risks, evaluate their influence, and sketch the required counteractions. This stage guarantees that none of the safety precautions is missed.

Support Effective Communication

One of the main reasons workplace mishaps happen is a lack of communication. Create open lines of communication for important data like permit specifics, risk-reducing strategies, and updates throughout the actual application.

Track Permission Life

Track permits issued through closure as well as from inception. Review their development often to guarantee adherence to safety standards and take quick care of any anomalies.

Make Use of Technology

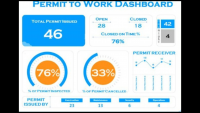

Digital PTW systems can offer real-time insights, simplify processes, and remove hand-made mistakes. Dashboards, automated alarms, and mobile access guarantee quicker decision-making and more seamless teamwork.

Check and Enhance

Examine your PTW system often to find mistakes and inefficiencies. Apply the knowledge to streamline procedures and guarantee ongoing enhancement of safety performance.

Also, read real estate management services best practices.

How does Factech’s Work Permit System help?

With its all-encompassing digital solution, Factech‘s work permit system is meant to surpass conventional PTW systems’ drawbacks. Here’s how it stands out:

- From request to approval and closure, automated systems streamline the whole PTW process.

- Dashboards give real-time tracking of permit conditions, therefore guaranteeing proactive decision-making.

- Mobile Access lets you remotely approve and access important data wherever.

- Automated reminders and updates let you notify stakeholders.

- For compliance checks and inspections, audit-ready reports provide thorough logs and exportable data.

- Through a strong and easy-to-use PTW system, Factech helps companies eliminate manual mistakes, lower delays, and improve occupational safety.

The bottom line

Ensuring worker safety and equipment integrity depends mostly on a work permit system. Using a formalized work process and guaranteed controlled and orderly execution of the tasks, helps to lower the risk of accidents and incidents.

Contact us for a free demo of how our expertise can help you achieve your business goals to the best.