Breakdown Maintenance

How to do breakdown maintenance effectively?

Breakdown maintenance is required due to the continuous use of machine, unit, or device until it breaks down. Breakdown or reactive maintenance is the maintenance performed on a piece of equipment that is not operatable anymore.

It cannot be scheduled in advance.FM companies need to redirect resources toward repairs every time equipment breakdown.

Maintenance Types for Breakdowns

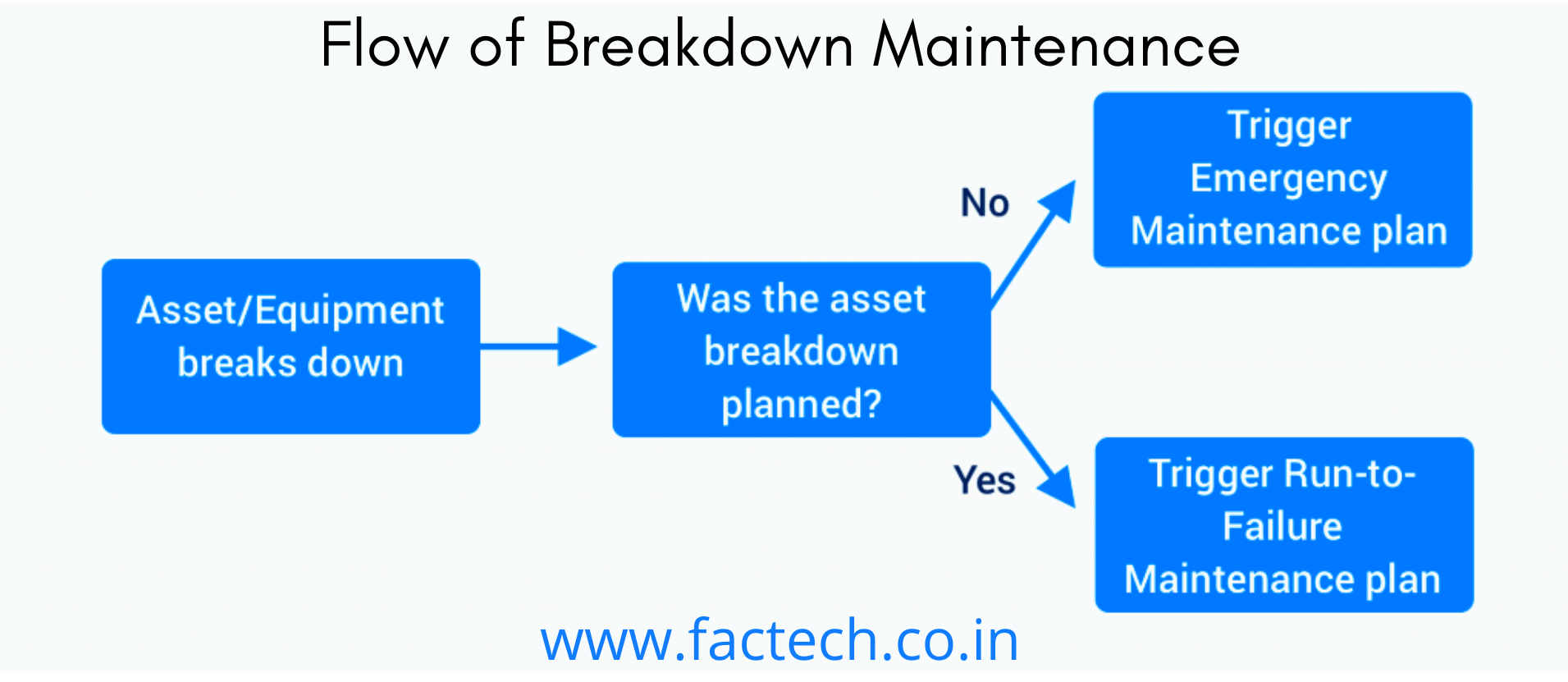

Run-to-Failure (RTF)

The failure that is expected to happen in the equipment is called planned or run to failure Maintenance.

This kind of plan needs to be properly documented and controlled. The facility team needs to be clear about which parts will be allowed to break down. And which needs to be maintained over course of time.

Emergency or Unplanned breakdown maintenance occurs when the equipment breakdown unexpectedly. Every facility needs a plan and resources in place for unplanned maintenance. Unplanned breakdowns are true and can happen. Though the frequency can be reduced drastically with predictive maintenance.

Maintenance Flow

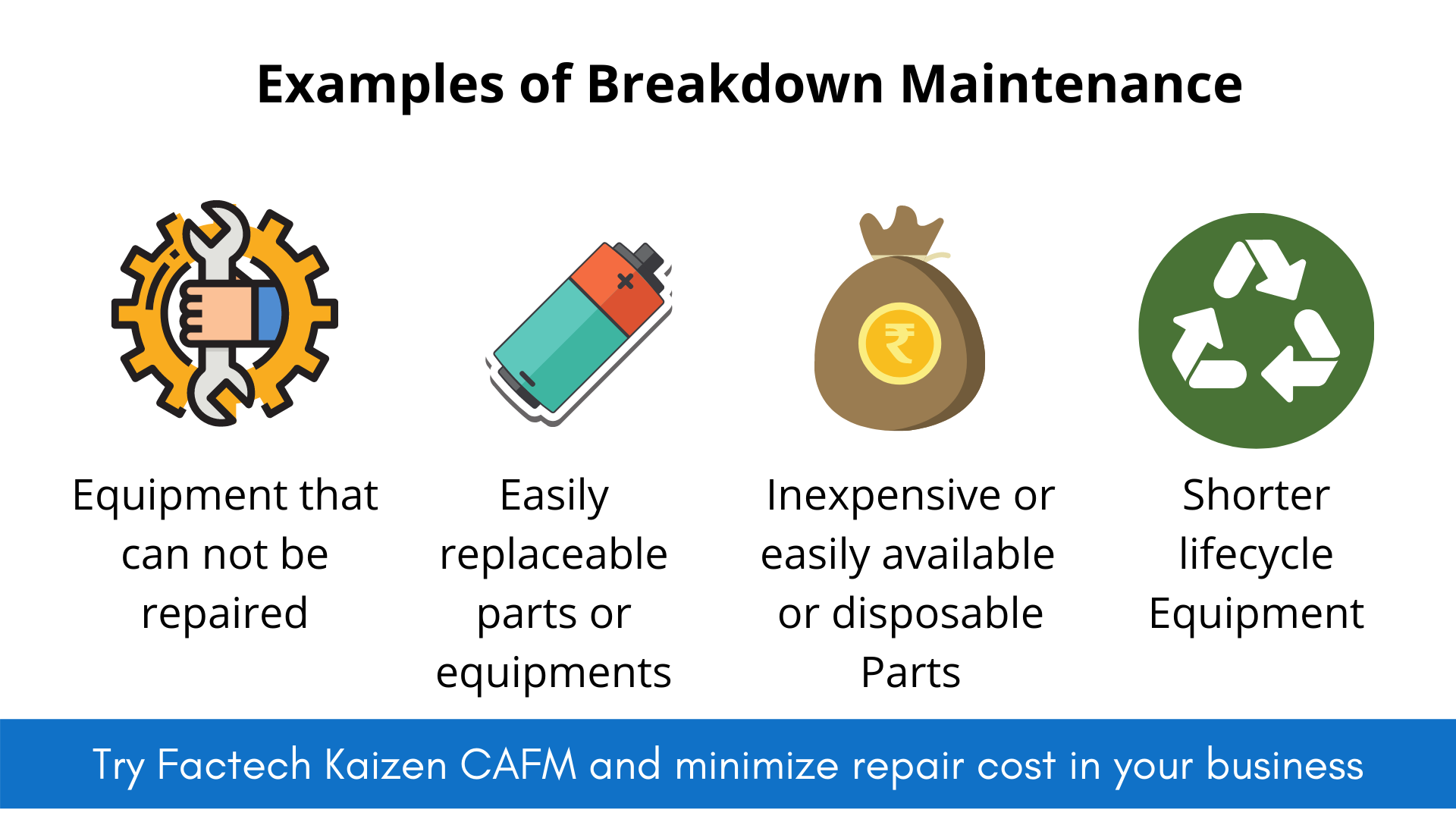

Examples

Though breakdown maintenance looks costly and unwanted. Breakdown maintenance makes sense in the below cases:

What are the pros and cons of Breakdown Maintenance?

PROS-

- Minimizes Cost of Preventive Maintenance

- Less staff required

- Simple and Easy to understand when maintenance is required.

- Extended component life cycle.

CONS-

- Costly fixes

- Decreased Asset lifespan

- Safety issues occur in case of breakdown

- Difficult to pinpoint the source of failures

Tips for efficient

Though breakdown maintenance sounds catastrophic. But if it’s planned and executed well, it can make a lot of sense for certain equipment. If reactive maintenance is unplanned it can lead to high cost, safety risks, and halted production.

Use CMMS or CAFM system to plan, record, and control breakdowns

A user-friendly CAFM or CMMS system can help you to plan and manage your breakdowns effectively. The CAFM system can provide you insights and relevant data to learn from heavy breakdowns

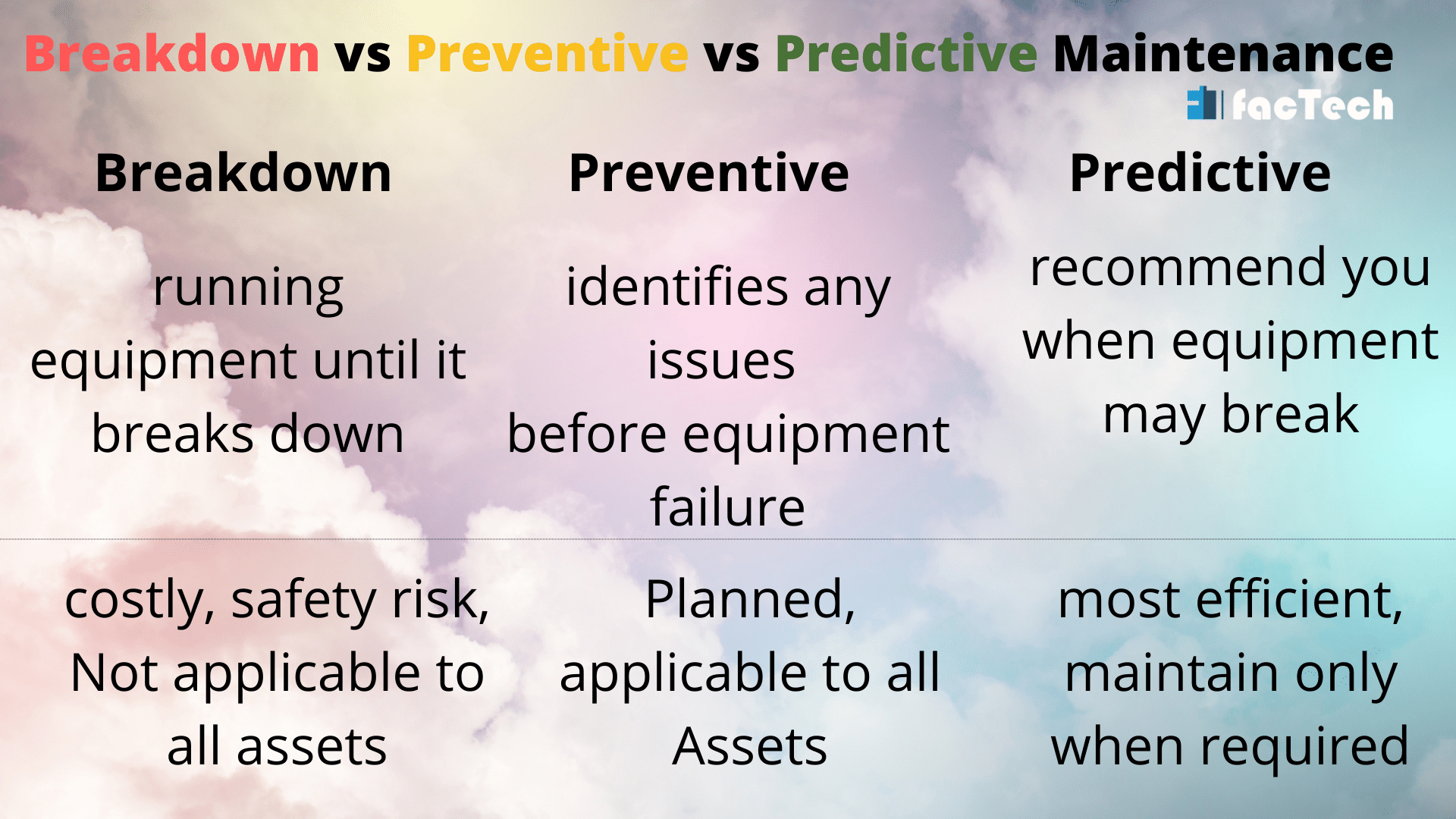

Tip 3: Move from breakdown to Preventive to Predictive Maintenance

An effective system like Kaizen CAFM can help your team to move from breakdown to preventive maintenance and then to predictive maintenance.

Technician doing breakdown maintenance in Mobile App

Difference between breakdown, preventive and prescriptive maintenance

Factech Solutions has built solutions for Facility Management including KAIZEN CAFM.

Improving Equipment Reliability with a Preventive Maintenance Plan